About

Shree Industry

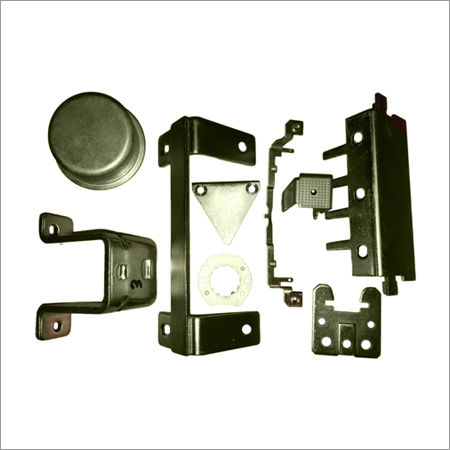

Precisely engineered sheet material press components & assembles for electrical and automobile industry applications.

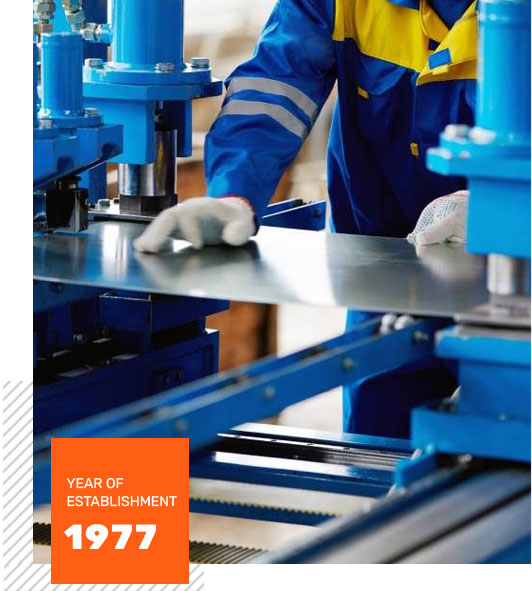

Shree Industry, a 1977 establishment headquartered in Mumbai, Maharashtra (India) serves the steel industry with precision engineered products like Sheet Metal Press Parts, etc. The ISO 9001:2008 certified company has its branches in Ahmadnagar and Vadodara. Presently, Mr. Vikas Rajpurkar is handling and managing the company, guiding and motivating all employees to perform their responsibilities with efficiency. The company is MSME 3 rated by the SMERA Ratings Limited.

Services

What We DoOur Company's Growth

Sustainable growth has been maintained over the years, which is evidentProduct Portfolio

Coil, M S Sheet, Copper Strips and Brass Coil are the basic material which we usedProduction Plants

We are having three modern production plants; all are ISO 9001:2008 certified

Let's Talk Business!

Please take a quick moment to complete this form and a business representative will get back to you swiftly

Clients

Back to top